Storage and Handling

To help ensure ease of storage and handling while maintaining free flowing properties, Hollow glass microspheres have been made from

a chemically stable glass and are packaged in a heavy-duty polyethylene bag within a cardboard container.

Minimum storage conditions should be unopened cartons in an unheated warehouse.

Under high humidity conditions with an ambient temperature cycling over a wide range, moisture can be drawn into the bag as the tem-

perature drops and the air contracts. The result may be moisture condensation within the bag. Extended exposure to these conditions

may result in “caking” of the hollow glass microspheres to various degrees. To minimize the potential for “caking” and prolong

the storage life, the following suggestions are made:

1.Carefully re-tie open bags after use.

2.If the polyethylene bag is punctured during shipping or handling, use this bag as soon as possible, patch the hole, or insert the

contents into an undamaged bag.

3.During humid summer months, store in the driest, coolest space available.

4.If good storage conditions are unavailable, carry a minimum inventory, and process on a first in/first out basis.

Dusting problems that may occur while handling and processing can be minimized by the following procedures:

1.For eye protection wear chemical safety goggles. For respiratory system protection wear an appropriate NIOSH/ MSHA approved resp-

irator. (For additional information about personal protective equipment, refer to Material Safety Data Sheet.)

2.Use appropriate ventilation in the work area.

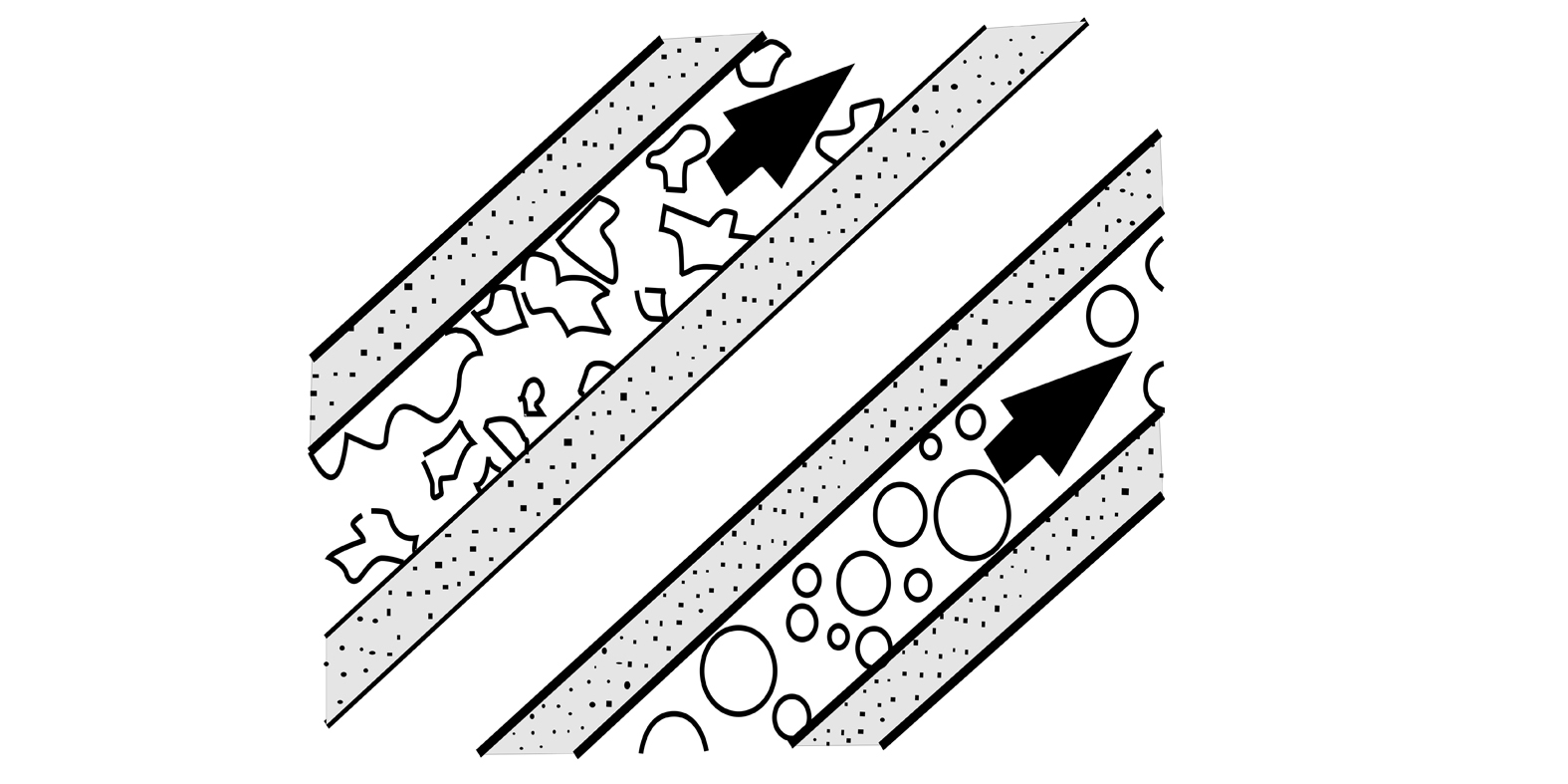

3.Pneumatic conveyor systems have been used successfully to transport hollow glass microspheres without dusting from shipping cont-

ainers to batch mixing equipment. Static eliminators should be used to help prevent static charges.

Diaphragm pumps have been used to successfully convey hollow glass microspheres. Vendors should be consulted for specific recommendat-

ions.

The high-performance hollow glass microspheres breakage may occur if the product is improperly processed. To minimize breakage, avoid

high shear processes such as high speed Cowles Dissolvers, point contact shear such as gear pumps or 3-roll mills, and processing pre-

ssures above the strength test pressure for each product.

Health and Safety Information

For product Health and Safety Information, refer to product label and Material Safety Data Sheet (MSDS) before using product.

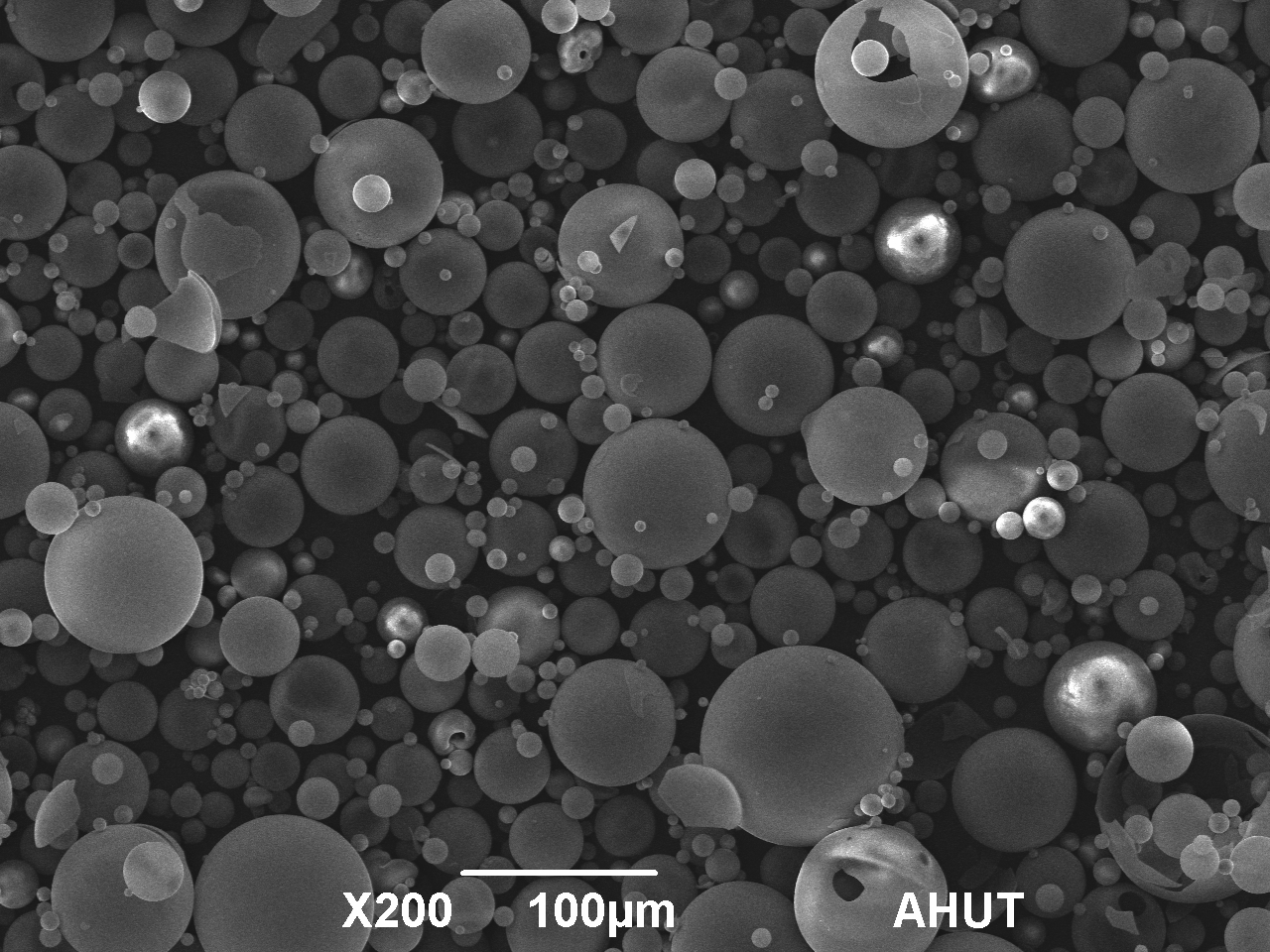

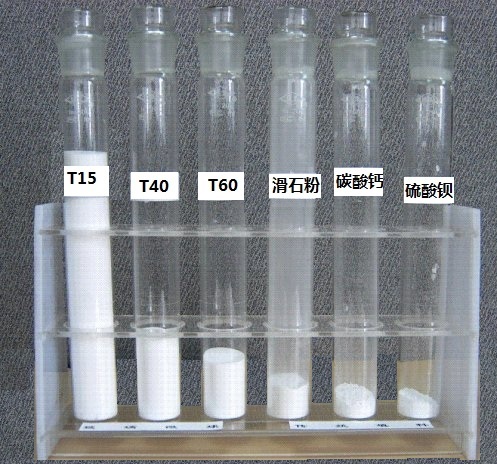

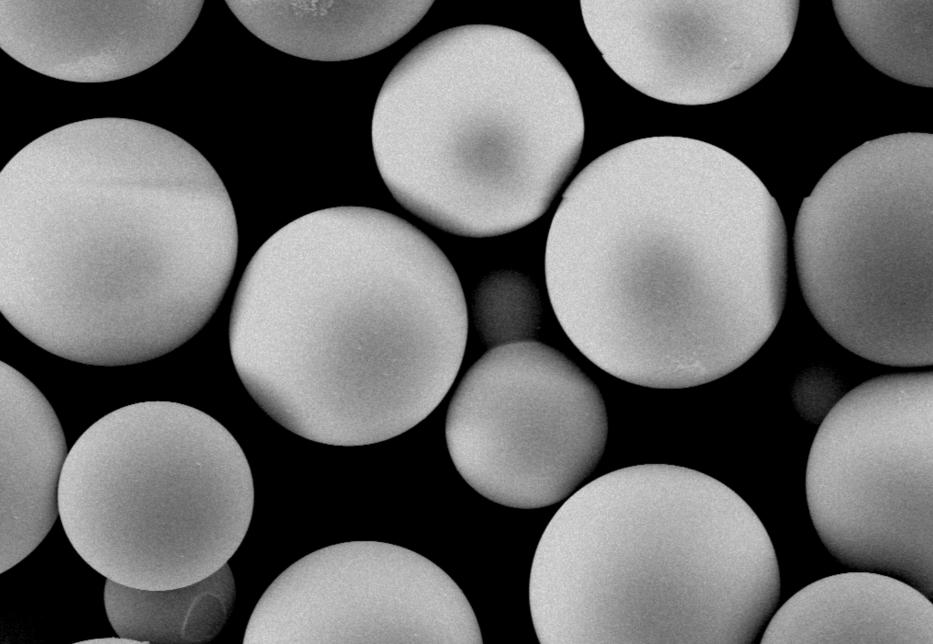

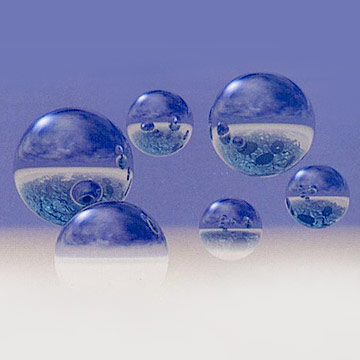

High-performance hollow glass bead is a kind of ultra-lightweight inorganic non-

High-performance hollow glass bead is a kind of ultra-lightweight inorganic non-