Sinosteel Maanshan Institute of Mining Research Co., Ltd., established in 1963 and directly subordinate to the former Ministry of Metallurgical Industry, is a large comprehensive research and development institution in China’s metallurgical mine field. We are one of the units approved early by the Academic Degree Awarding Committee of the State Council to have independent right to award the master academic degree and one of the units approved by the State Economic and Foreign Trade Ministry to have the right to import and export products. Our firm developed into a scientific and technological enterprise in 1999 and now belongs to China Sinosteel Group.

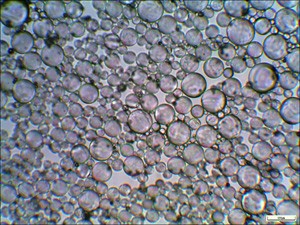

Sinosteel Maanshan Institute of Mining Research Co., Ltd. is a National Torch Program High-tech Enterprise. Our firm has outstandingly completed a series of major national scientific and technological projects, including “the Sixth Five-Year Plan” and “the Eleventh Five-Year Plan”, and published over 2,500 academic papers at home and abroad. Our firm has more than 1,700 sets of all kinds of equipment and facilities and over 50 supporting pilot plants. Sinosteel Maanshan Institute of Mining Research Co., Ltd. cooperates with Chinese Academy of Sciences to develop an industrialized technique to produce high-performance hollow glass microspheres, filling a gap at home.

Sinosteel Maanshan Institute of Mining Research Co., Ltd. is located in Maanshan — known as the National Civilized City, the National Sanitary City and the National Garden City. Maanshan is described as “a Branch of Flower along the Yangtze River”. The hollow glass microsphere company (subsidiary of Sinosteel Maanshan Institute of Mining Research Co., Ltd.,) covers an area of 20,000m2, with several large-scale standard plants totally up to 10,000m2 and integrated modern office buildings of 7,000m2. Our company has obtained ISO9001:2000 quality management system certificate. In the fierce market competition, our company holds the business spirit of “quality, honesty, good service” and relies on advanced technology and strong strength to provide customers with better products and services.