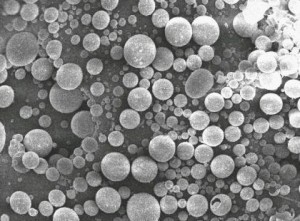

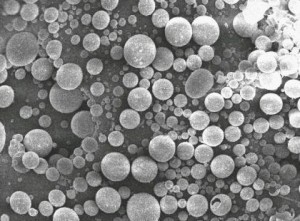

Investigation of hollow glass microspheres (HGB) type and amount, type and amount of silane coupling agent and other effects of hollow glass microspheres / low-density polyethylene (LDPE) density and mechanical properties of composite materials. The results showed that: 20 parts of glass beads is more appropriate dosage; coupling agent A-172 glass beads treatment is better than KH550; when the A-172 dosage of 1.0% optimum mechanical properties of composite materials, including impact strength than before treatment increased by 24%, the tensile strength than before treatment increased by 18%; scanning electron microscopy (SEM) showed significant improvement in A-172 glass beads combined with LDPE interface. Hollow glass beads for weight loss is not as LDPE LDPE chemical foaming obvious, but it can better take into account the “light” and mechanical performance requirements.

In the automotive industry, construction industry and other applications, often need to avoid a significant reduction in the mechanical properties of plastics on the basis of the original as much as possible to reduce weight and reduce costs. Effective method of reducing the density foamed plastics modification, adding lightweight fillers. The use of azo dimethylamine (AC) chemical blowing agents for foamed plastics modification, can significantly reduce the density of the material, but there are difficult to accurately control the degree of foaming, nonuniform cell structure and other drawbacks, resulting mechanical properties (tensile strength, modulus, etc.) deteriorate.By adding a lightweight filler material way to reduce the weight of these problems can be avoided. Typical lightweight filler is hollow glass beads. This is a powdered inorganic filler, can be taken directly from the glass system, it can also be isolated from coal ash. Its microscopic structure wrapped with a certain amount of gas in the thin-walled, closed microspheres, the relative density is generally 0.4 to 0.7, lower than usual relative density of plastics. Hollow glass microspheres have a smooth spherical surface, it can reduce the weight of the material at the same time, improve mobility and surface quality composites. Hollow glass beads also has a low thermal conductivity, heat resistance, corrosion resistance, and controllable size advantage.

Posted by admin on October 20, 2017 at 1:30 am under Uncategorized.

Comments Off on Hollow Glass Bead Filled LDPE material properties.

There are many preparation methods of hollow glass microspheres, such as flame, into the ball inside the furnace, Si – GDP (silicon doping glow discharge polymerization coating) spherical shells pyrolysis and sputtering method, etc. In many ways, furnace into a ball of mature technology, prepared by the quality of microspheres (concentricity, sphericity and wall thickness uniformity, etc.) is higher, and is suitable for batch production, hydrogen storage with hollow glass microsphere preparation is one of the main candidate method.Furnace into a ball method according to different raw material state can be divided into droplets method and dry gel method. Ball temperature range of the main equipment is more SPC vertical high temperature furnace, droplet method and the solution of sodium silicate on raw materials, raw materials by droplet generator change uniform droplets into the high temperature furnace, and raw materials for high gel method of dry gel particles. Using the furnace into the ball technology preparation of glass microspheres in 150 ~ 250 microns in diameter, wall thickness in 0.9 ~ 40. Mu m between. The diameter of the microspheres and the wall thickness can be adjusted by using condition.

Hollow glass microspheres hydrogen storage

Microspheres filling hydrogen equipment main function is to simply by changing the empty ball external hydrogen pressure and microsphere environment temperature, in order to realize the empty core ball of hydrogen. Hydrogen plant by vacuum system, high pressure gas source and control part, plenum chamber and road.Control part of the main function is to set and control of temperature, record the gas chamber in the process of temperature, pressure and the relation curve of time, temperature and pressure of gas chamber upper limit alarm and processing, etc.25 mpa plenum chamber maximum working pressure, temperature range for the room temperature to 450 ℃, the heating rate is 3 ~ 15 ℃, min 1, in the process of heating up the biggest deviation is less than 30 ℃, the maximum overshoot temperature less than 10 degrees Celsius, the temperature of the heating process to the constant temperature fluctuation time less than 20 min, the temperature drift when temperature is less than 0.5 ℃. Hollow glass microspheres can be studied by using the device condition of air pressure balance time and specific air pressure inside the ball.

Posted by admin on October 13, 2017 at 2:27 am under Uncategorized.

Comments Off on Hollow glass microspheres high-pressure hydrogen storage technology.

According to reports, the use of fly ash cenospheres modified ultrafine polymer, one can play to the characteristics of the hollow microspheres, the mechanical properties of the polymer, wear resistance, insulation, insulation performance has been greatly improved, new high performance polymer materials. On the other hand, the use of polypropylene or polyethylene suitable for such modification of ultrafine hollow microsphere masterbatch made by blending can add mechanical properties of products, wear resistance, heat insulation performance greatly improved, while reduce material costs, material ideally suited for high rigidity, toughness requirements of injection molded products industry.

According to reports, the use of fly ash cenospheres modified ultrafine polymer, one can play to the characteristics of the hollow microspheres, the mechanical properties of the polymer, wear resistance, insulation, insulation performance has been greatly improved, new high performance polymer materials. On the other hand, the use of polypropylene or polyethylene suitable for such modification of ultrafine hollow microsphere masterbatch made by blending can add mechanical properties of products, wear resistance, heat insulation performance greatly improved, while reduce material costs, material ideally suited for high rigidity, toughness requirements of injection molded products industry.

Posted by admin on September 28, 2017 at 6:34 am under Uncategorized.

Comments Off on Ultra-fine glass hollow bubble composite advent.

Optical glass beads, as a new product in the glass industry. It has a certain chemical stability, mechanical strength, electrical insulation and be rounded, uniform, and good liquidity.Its most unique properties with the original glass transparency, with the return of retroreflective performance. Especially the use of different conventional glass raw material of high refractive index glass beads much broader range of applications than the ordinary type beads, in addition to serving highways and airports and all kinds of road marking paint sign board outside,Can also be made reflective clothing, reflective rain gear, a traffic policeman on duty at night with reflective sleeves, etc. It can greatly reduce traffic accidents at night or in rain and fog days. Early in the 1960s the US government to develop a “federal highway regulations” provides highway lane, traffic signs, road signs, road signs and so on.In the headlights illuminated necessary to achieve the standard luminous indicators improve visibility distance traffic signs, the need to adapt to the highway. That this is to reduce traffic accidents most cost-effective way.”International maritime rescue organization” has also been stipulated that all vessels with a life buoy, life jackets and all life-saving equipment and the corresponding buoy flags are required glyphs reflective material with a high refractive index glass beads made.Helicopters and lifeboats to sea only available light to detect targets at night and rain and fog days in the rescue time and space. So that in addition, the use of high refractive index glass microspheres made of other reflective materials are also widely used in other industries, for example: large oil derrick, tower, movie screen, large public spaces such as billboards.

Posted by admin on September 21, 2017 at 6:44 am under Uncategorized.

Comments Off on Optical glass beads.

M.Palumbo etc. The effect of the content of hollow glass microspheres compression performance of the material, and the compression elastic modulus of the material was modeling analysis.JRMAlmerda and other hollow glass microspheres were sieved particle size, the influence of the particle size of the material compression performance, found that the smaller the particle size of the hollow glass beads, beads and material strength is greater. LJGibson and other preparation techniques, performance testing of composite foam detailed study, and study the mechanical properties, thermal properties, electrical properties and acoustic properties of the material and the like.EMWouterson such as the use of epoxy resin as matrix, K15, K46 hollow glass microspheres and BJO-093 phenolic resin microspheres prepared by filling density of 0.8g / cm3, a compressive strength of 54MPa of syntactic foam, was found with microspheres volume fraction increased from 0% to 50%, the stretched composite foam strong, flexural strength and flexural modulus are lower, and the effect of microstructure on the properties of the foam.N.Gupta such as the use of hollow glass microspheres filled vinyl ester-based system, a composite foam, the tensile and compression tests found that the modulus and strength of the base material is quite pure, but the strength and modulus of the composite foam is higher pure substrate.

Low density hollow glass beads filled, composite foam density plays a decisive role

Posted by admin on September 14, 2017 at 5:54 am under Uncategorized.

Comments Off on Progress resin / hollow glass microsphere composite foam.

Hollow glass beads spherical structure makes the impact force and stress have a good dispersion, added to the paint can well improve the resistance to external impact properties of the film, and the coating can be reduced due to thermal expansion and contraction the stress cracking.

Hollow glass beads is a small density, glass microspheres lightweight, high strength. The main ingredient is Sio2 and Al2o3, because of its unique chemical properties, physical properties, and hollow spherical, compared with ordinary glass beads, light weight, low density, good heat insulation performance characteristics, is thermal insulation coatings the main raw material. Because of its smaller particle size, equal to or greater than the ordinary paint fineness of the filler, which can be added directly to the filler coating systems, the coating having a cured coating film formed by thermal insulation properties.

Hollow glass microspheres Application Features:

There filling performance energy efficient, low low oil, density, added 5% (wt) will be able to make the finished product increased by 25% to 35%, so as not to increase or even reduce the cost per unit volume of the coating. Hollow glass beads particles confined hollow spheres added to the coating formation of many independent microscopic cavity insulation, thus greatly improving the coating on the thermal and sound insulation, play a very good thermal insulation and noise reduction effect. The coating has a more waterproof, anti-fouling, corrosion resistance. When the surface of the hollow glass microspheres are chemically inert chemical resistance, as the film tightly packed particles of glass beads, the formation of low porosity, the coating formed on the surface of the moisture and corrosion caused by the blocking effect of ions protective film, played well protective effect.

Posted by admin on September 7, 2017 at 7:34 am under Uncategorized.

Comments Off on Hollow glass beads used in insulation coatings industry.

Traditional buoyancy materials generally use polyurethane foam, epoxy foam or other foam plastic, although the cost is low, but the pressure strength is low, soaking for some time, will lose water buoyancy, the use of poor reliability. People began to develop lightweight high-strength solid buoyancy materials to replace the traditional buoyancy materials for deep-sea resource exploration and mining.

At present, the use of high-performance hollow glass beads filled with polymer synthesis of deep-sea high-strength buoyant material has been applied. It is made of epoxy resin

As the substrate, filled with a certain amount of high-performance hollow glass beads and other additives into a light buoyant material. In the deep sea oil and gas field exploration and operations to reflect the light, resistant to seawater corrosion, dimensional stability, high strength, good insulation and many other advantages.

Posted by admin on August 31, 2017 at 6:20 am under Uncategorized.

Comments Off on Application of hollow glass microbeads.

1977 Charles .G. Wade US Atlas Powder Company proposed not adding the sensitizer, only 1 on the 6th detonators reliable emulsion explosives detonated. Its main feature is the use of sensitization of hollow glass microspheres.

Thin-walled hollow glass beads from sodium borosilicate material with a special process, closed the tiny sphere, the sphere inside the parcel certain amount of gas, its specific density, low thermal conductivity, low oil absorption, particle size and chemical composition controllable superior performance, which makes it very suitable as emulsion explosives sensitizers.

Hollow glass microspheres uniformly distributed stable formation of numerous tiny bubbles of space in explosives. In the role of external initiation impulse, each bead by adiabatic compression local temperature form burning point, and detonated outside the mechanical energy is focused on those burning point is at a temperature high enough to cause burning and oil phase oxidant the violent exothermic chemical reactions such as decomposition, to detonation.Internal phase emulsion explosive matrix supersaturated solution, the density is large, liquid beads were separated by the film; the Foreign Secretary for the film, the density is relatively small, in the long-term storage in the aqueous phase has a tendency to sink, the oil phase has a floating trend, final lead to breaking. Most of hollow glass microspheres diameter between 10μm to 150 μm, and a matrix of internal phase droplet diameter of 10-1μm to 1μm, Foreign Minister film thickness of 10-3μm to 10-2μm.After addition of cenospheres, nearly one-third of the space of the substrate surface granularity “huge” hollow microspheres occupied surface of each bead around the oil droplets are associated with many closely together. They play the role of care afloat stabilizer.

In summary, hollow glass beads is a multifunctional additive in emulsion explosives.

Posted by admin on August 24, 2017 at 7:10 am under Uncategorized.

Comments Off on Thin-walled hollow glass beads from sodium borosilicate material.

For example: by adding water dilution, plus hollow ceramic microspheres method, add the foam method. Dilution water and add the cement foam-regulating unstable performance. Plus hollow ceramic microspheres law, and hollow ceramic beads themselves strong enough, in the slurry injection wells can break, resulting slurry density rises.And in the deep mining of oil, adding high-performance hollow beads of grout has a certain fluidity in the process of injection wells, grout injection wells, it can quickly condense, and reached a considerable strength in the short term, the hardened cement pasteIt has good stability and impermeability, corrosion resistance and so on.Temperature and pressure at the bottom of the well with the depth of enhancements and improved every depth 100m, an increase of about 3 degrees Celsius temperature, pressure increase 1.0-2.0mpa. Depth of 7000 meters above the bottom hole temperature up to 200 degrees Celsius, and pressures up to 125mpa.Thus high temperature and pressure, to influence various properties of cement, oil well cement production and use of the most important issues. The strength of the cement slurry high temperature decreased significantly. Added with cenospheres slurry, not only to reduce the density and can withstand prolonged high pressure and high temperature strength, this lightweight cement outperforms other conventional light cement.

Posted by admin on August 18, 2017 at 6:12 am under Hollow Glass Microspheres.

Comments Off on Hollow glass microspheres in the application of the cementing cement.

Sorter is using gravity separation, sorting consists of three sizes settlement box. In the lower portion of each settling tank, are provided with discharge means, when the gas stream containing fly ash from the intake pipe into the settling tank, since the gas flow passage cross section is increased, the gas flow rate drops quickly, fly ash by itself the force of gravity. Part of the gradual drop in the settling tank, according to the principles and other lower, heavier coarse particles, honeycomb vitreous quartz, mullite, solid beads, iron beads and large particles of carbon particles were mostly settled in the sorter within . There are some small hollow glass beads, beads, etc. Superfine into the air separator.

By the action of the separator is in the gas stream during rotation of the centrifugal force on the particles in the inertia, so that particles are separated out from the gas stream. The main form of cyclone separator group, by sinking down box channel tiny hollow beads into the air separator, sorting through a two-stage cyclone group can most small cenospheres sorting out, the remaining very small amount of ultra-fine beads and finally with the air enters the collector.

Collector terminal sorting apparatus, it is both the purification apparatus is recovered ultrafine microbeads collector. Process uses a pulse bag collector, it is not selected by the separator down the majority of ultrafine beads collected.

Posted by admin on August 11, 2017 at 6:23 am under Uncategorized.

Comments Off on How sorting hollow glass beads.