Glass bubbles are finely dissipated, free-streaming fine particles created by dissolving a unique glass equation which comprises of an inert blowing specialist which makes the liquefied glass particles swell into an empty air pocket. The subsequent glass bubbles are water-safe, and viable and synthetically stable with different materials that are utilized for aberrant food contact applications. In the coming years, material innovation has developed to make bubbles with high solidarity to thickness proportion, subsequently empowering its utilization in requesting polymer handling activities.

On the flipside, inflexible and underlying properties of glass bubble froth give an extra protection worth to dividers and lodgings. Moreover, glass bubbles convey weight decrease for thermosets, thermoplastics, and elastomeric polymer substrates. This aides lessening transporting cost and furthermore facilitates establishment issues. The expansion of glass bubbles to polymers changes its actual property. Adding glass to bubble polymers makes the composites stiffer when contrasted with its unique unfilled base gum. This is valuable in the assembling of solid yet light lodgings and parts.

Nevertheless, the quick extension of the auto business, particularly in the U.S., is expected to help the market during the gauge time frame. Besides, severe discharge control guidelines in the U.S. what’s more, different nations in the Europe is expected to fuel the interest for glass bubbles at a huge speed in the years to come.

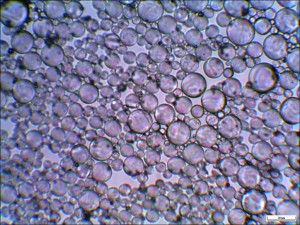

Additives, particularly inorganic solid minute particles, have significantly contributed to the development of the polymer industry. Depending on their geometry and chemistry, additives provide polymers with better physical, thermal, electrical, mechanical, and dimensional properties. Glass bubbles are finely scattered, free-flowing fine particles with an average diameter of 15-65µm, and consists of thin-walled, sphere-shaped glass particles (0.5-1.5µm). They were first developed in the 1960s, as an extension after the production of solid glass beads. Glass bubbles are produced by melting a special glass formula which consists of a latent blowing agent which causes the melted glass particles to swell into a hollow bubble. The resulting glass bubbles are water-resistant, and compatible and chemically stable with various materials that are used for indirect food contact applications. In the recent years, material technology has evolved to manufacture bubbles with high strength to density ratio, thus enabling its usage in demanding polymer processing operations.

Glass bubbles provide design solutions for innovative users and new and elite materials. Moreover, they provide polymers with low-density that can be related directly to insulation properties and thermal conductivity. The three polymer types, viz., high impact polystyrene (HIPS), polyurethane (PU), and polypropylene are commonly used in applications such as housings, and walls or as foam for insulation, especially in the case of thermoset polyurethane (PU). PU foam for insulation are made with chemical blowing agents and are usually attained at very low density (0.20 – 0.40 g/cc). The PU composite density with glass bubbles is in the range of 0.76 – 0.95 g/cc; therefore, they are not compatible with urethane for attaining maximum insulation properties. However, rigid and structural properties of glass bubble foam gives an additional insulation value to walls and housings. Furthermore, glass bubbles deliver weight reduction for thermosets, thermoplastics, and elastomeric polymer substrates. This helps reducing shipping cost and also eases installation issues. The addition of glass bubbles to polymers changes its physical property. Adding glass to bubble polymers makes the composites stiffer as compared to its original unfilled base resin. This is useful in the manufacturing of strong yet light housings and parts.

The glass bubbles market can be segmented based on application and region. In terms of application, the market can be segmented into automotive and commercial vehicles, aircrafts, and recreational and marine vehicles. In terms of geography, the glass bubbles market can be segmented into North America, Europe, Asia Pacific, Middle East & Africa, and Latin America. North America dominated the global glass bubbles market in 2016, followed by Europe, and this trend is anticipated to continue during the forecast period. Moreover, rapid expansion of the automobile industry, especially in the U.S., is anticipated to boost the market during the forecast period. Furthermore, stringent emission control regulations in the U.S. and various other countries in the Europe is anticipated to fuel the demand for glass bubbles at a significant pace during the forecast period. The market in Asia Pacific is expected to expand at a considerable pace during the forecast period owing to the implementation of stringent government norms concerning volatile organic content (VOC) emissions from automobiles in countries such as China and India, while the market in Middle East & Africa and Latin America is likely to expand at a moderate pace during the forecast period.

Key players operating in the global glass bubbles market include 3M, Sinosteel Maanshan New Material Technology, and others.

FROM:Transparency Market Research