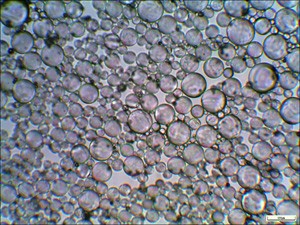

Microsphere is a term used for small spherical particles with diameters of the Order of the micrometer (typically 1 pm to 1000 pm (1mm)). The microspheres are sometimes called microparticles.

microspheres can be manufactured from various natural and synthetic materials. Glass microspheres, polymer microspheres and ceramic microspheres are commercially available. Solid and hollow microspheres vary greatly in density and, therefore, are used for different applications. The hollow microspheres are commonly used as additives to reduce the density dun material. Solid microspheres have numerous applications depending on what material they are constructed and what size they are.

Polyethylene and polystyrene microspheres

are two most common types of polymer microspheres.

Polystyrene microspheres

are commonly used in biomedical applications because of their ability to facilitate processes such as cell sorting and precipitation immunio. Proteins and ligands on polystyrene absorb easily and permanently, which makes polystyrene microspheres suitable for medical research and biological laboratory experiments.

Polyethylene

microspheres are commonly used as permanent or temporary care. Lower melting temperature polyethylene microspheres allows to create structures and porous ceramic materials dautres. High sphericity of polyethylene microspheres, as well as the availability of color and fluorescent microspheres, makes them highly desirable for the visualization and the analysis of the flow of fluid flow, microscopy techniques, health sciences, troubleshooting processes and applications Much research. Polyethylene loaded microspheres are also used in digital electronic paper displays.

Glass microspheres are mainly used as a filler and volumizer for weight reduction, road safety reflector, additives for cosmetics and adhesives, with limited applications in medical technology.

glass bubble;

Ceramic microspheres are mainly used as the grinding medium.

microspheres vary considerably in quality, sphericity, luniformité size and particle size distribution. The microsphere must be selected for each application.

We believe that the microspheres are Mon least understood commercial products. Most people associate microspheres with their use as filler in plastics and composite materials (hollow glass microspheres). This nest quune many applications.

THE USE seconds less microspheres is included in cosmetics and personal care industrys. Ceramic microspheres and polyethylene are used in cosmetics to create a soft and silky texture, and to provide a filler for reducing wrinkles on the skin. The personal care industry use polyethylene microspheres exfoliating agents in shampoos and shower gels (colored objects in suspension).